1401151738RM-FF1312001100Copyright © 1985-2014 by Roberts Electric Service, Inc. a California Corporation and Copyright © 2014 by Lunchtime Solutions ABN 95691345690 an NSW Business Entity in Association with Roberts Electric Service, Inc. All Rights Reserved.  |

Wednesday, 15 January 2014

Ref: 1401151738RM-FF1312001100-Accessibility-Scooter-Motor-Faults

Dear Mr. Barry Poynting,

Via Email: (removed for privacy)

Apologies for this delayed report.

Primary Complaint: Accessibility scooter fails to operate in a consistent manner especially under load.

Primary Observation: Scooter is in good condition and appears well maintained. Scooter did not operate under power at first demonstration testing. Fault analysis was requested by Customer.

Notes: Accessibility scooter was provided for review and testing. All components pass visual inspection. All components pass mechanical non-powered testing. All components pass electrical resistance checks.

Notes: Customer reports that other technicians have worked on this unit in the past. Customer was informed that the “reverse motor” was faulty. Customer was left with the impression that there were two motors in the unit and one of them was “bad”.

Notes: This accessibility scooter only has one DC motor. The reverse and instant stop functions are achieved through a timed polarity swapping mechanism in the controller circuits not via a separate motor.

Fault Testing: Tested controller for proper operation with inputs triggered to achieve the necessary outputs to perform all apparent functions. Tested batteries and wiring to confirm the loading ability was intact.

Result: Controller, batteries and wiring all pass.

Target Subject: Fault analysis of the DC drive motor.

Notes: Upper brush cap removed as would be expected and the brush and socket were in good condition.

Notes: Lower brush cap did not remove; it appeared to be epoxied in place. Customer was given the choice to continue or stop the fault analyses at this point as invasive action would be necessary to continue. Customer chose for us to continue.

Target Subject: Structural analysis of the brush cap and socket.

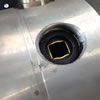

Method: Excavate the cap from the motor housing via dremel. Excavate the brush and brush components from socket using mechanical means as pictured below.

Findings: Refer to attached photos for clarity of findings.

Conclusive Findings: The lower brush was fixed into position by solidified plastic which was produced by the melting of the socket housing. This also “melted” the cap into place.

Progression / Causes: Examination of the brush material conductor connection and brush material revealed an old fracture in the brush material, likely from the brush manufacturer as a fault in the armature cannot cause this type of fracture. This fracture followed through to the conductor insert connection causing intermittent conductivity. The intermittent connection to the conductor caused the conductor and feed lead to obtain a “red hot” condition in the distant past based on the metal oxidation patterns. The melted socket material maintained the connection between the brush material and conductor by encasing the same and preventing the brush material from completely fracturing and properly failing. There was no evidence of recent or repeated melting of the socket enclosure.

Notes: There was no evidence that either brush cap had been removed nor the brushes inspected since the manufacture and assembly of the motor, tale-tale signs of access would normally be noted.

Conclusion based on verbal descriptions by Customer: Customer states that he has complained of intermittent power for several years and had finally “given up” with the repair personnel and supplier of the accessibility scooter. It is our inclination to believe this problem is a long term manufacturer defect as the brush and motor would have passed most testing unless substantially loaded and under vibration stresses, which is not typically part of the fault analysis or assembly process. Additionally, motors are provided to the assembly company as a sealed unit and there is no need to open them up for inspection at this point.

Notes: Customer has requested the brushes replaced and the socket repaired. This repair cannot be completed in this manner due to safety standards and public liability issues. The motor is a sealed unit and must be replaced as a whole sealed unit after this type of damage. Brushes can only be replaced if the armature and brush socket are both in good condition. The damage to the existing brush socket may inhibit the scooter from properly stopping - we cannot accept this risk.

Any questions, don’t hesitate to ask.

I can be reached on my mobile at 0438-719-932.

Thank you,

Along with a copy of this report, original hi-resolution versions of the below photos can be found at:

Report: 1401151738RM-FF1312001100-Accessibility-Scooter-Motor-Faults.pdf

Photos: http://www.robertselectricservice.com/cc/1401/1401151738RM-Motor-Fault/images.htm

Attached photos as referenced by above text: